JLCPCB has become a household name in the PCB design and manufacturing community thanks to its extremely competitive prices, fast online ordering process, and ability to deliver 1-2 layer to multi-layer PCB products in quantities of just 5-10 boards. However, as with any manufacturer, there are strengths and limitations that you need to consider before ordering JLC boards directly.

Another option that many businesses and individuals in Vietnam consider using is the service of domestic intermediaries – partners who can act as a bridge between customers and JLCPCB or other PCB manufacturers.

Through this article, Hatakey Electronics hopes to help you have a more general view of the advantages and disadvantages of ordering directly from JLC and through domestic intermediaries so that you can choose the unit that suits your needs.

1. Analysis of the advantages and disadvantages of ordering JLC boards

1.1. Advantages of ordering JLC circuits directly

Reasonable price

Compared to other international PCB manufacturers such as PCBWay, Elecrow, ALLPCB, PCBCart…, JLC’s price is relatively competitive. Prototype projects or small-volume production can be produced with starting prices from only 2 USD for single-layer or double-layer circuits. This is a great advantage to help reduce product development costs.

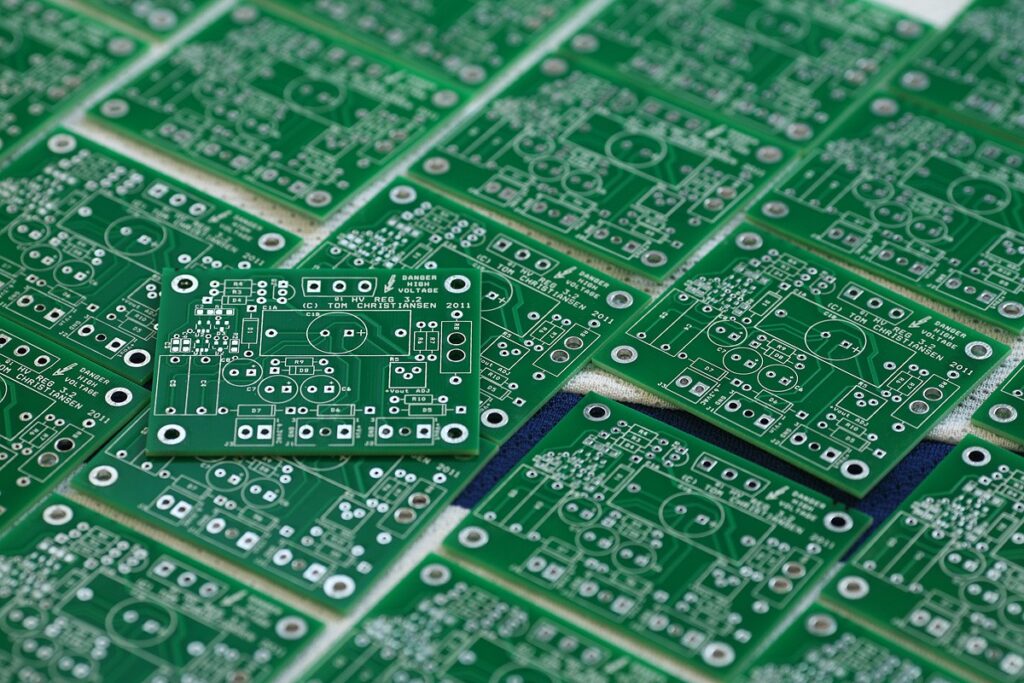

Figure 1. Sample price of 1-2 layer circuit when ordering JLC circuit from only $2/5 circuits

Fast delivery time

Production and delivery time to customers in Vietnam is only 5-7 days including customs clearance time. Although slower than ordering fast circuit processing from domestic factories, if comparing the quality and risk of circuit errors due to processing, JLC is the top choice.

Good quality within the price range

JLC is considered a good quality mid-range manufacturer in the market. PCB products from JLC have been receiving positive feedback from the Vietnamese and international electronics community from circuit quality (Minimum width 0.1 mm), coating, copper layer thickness, plating, to milling grooves… There is almost nothing to complain about when ordering popular circuit boards from JLC.

Convenient Online Ordering

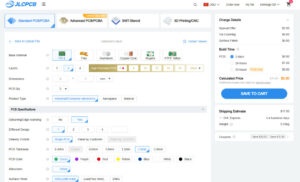

The JLCPCB website allows you to upload Gerber files, select production parameters, and place orders quickly. This process has been optimized to make it easier for customers to order circuits. In addition, the system also allows customers to check production Gerbers before the order is placed, helping to minimize the risk of design errors.

Figure 2. Intuitive interface when ordering JLC circuits

Diverse services

In addition to printed circuit manufacturing, JLCPCB also provides PCB assembly (PCBA), stencil printing, 3D printing, CNC machining and other solutions. This helps customers easily solve the entire production process. In addition, JLC also provides advanced options, the ability to customize according to needs if customers are willing to pay extra fees.

1.2. Disadvantages of ordering JLC circuits directly

In addition to the above advantages, ordering circuits directly from JLC also has some limitations that you need to consider before ordering:

Not the best price?

JLC can be considered an international circuit manufacturer with competitive prices, but compared to domestic Chinese manufacturers with similar quality, it is still not the unit with the best price. In addition, because the ordering process on JLC is fully automated, it is also difficult for you to negotiate a good price for quantity orders.

The price of soldering and assembling circuit boards (PCBA) from JLC is still higher than ordering soldering from domestic manufacturers. In addition, JLC’s source of components (LCSC) is also limited and the price is not as good as that of other suppliers.

When you order sample circuits, the price difference is almost negligible. But with large mass production orders from a few square meters to several dozen square meters or more, finding a low-cost manufacturer is especially important. Especially in a harsh environment like the electronics industry, where you always have to optimize production costs to maintain a competitive advantage.

Flexibility in production

Because the process at JLC is fully automated, when errors or mistakes arise due to design, it will be very difficult to handle. Especially when production has begun. This can cause great damage to quantity orders when there is a misunderstanding between the customer and the manufacturer or there are errors or mistakes in the design file.

Limited production capacity

As a mid-range manufacturer, JLC also has limitations in production capacity from the options of circuit material types to errors and limitations in technical parameters such as circuit size, copper thickness, plating thickness, thickness and structure of circuit layers (PCB Stackups), no support for blind/burried Via… Therefore, you need to carefully refer to the production capacity as well as check the design file before processing.

If your products are standard circuits with no special requirements, JLC seems to be the right choice, but if your products are highly complex, such as high-frequency circuits… requiring layer stackups to be customized according to requirements other than those from JLC or processed on special types of chips, you need to find a high-quality manufacturer.

Technical knowledge required

Direct ordering requires customers to have a solid knowledge of file formats (Gerber, BOM, picknplace coordinate files) and production inspection processes, which can be difficult for newcomers who are not familiar with the production process and specialized technical terminology. In addition, JLC only supports English, which can also be difficult for customers.

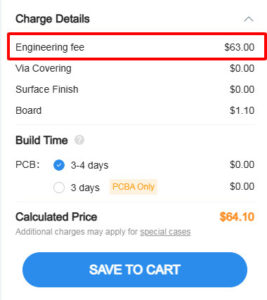

Additional fees when ordering JLC circuits

When ordering circuits from JLC, there are sometimes additional fees that make the circuit price much higher if you are not a professional. These additional costs often come from your choice of special circuit parameters or the design has components that exceed the factory’s production capacity or are difficult to process, causing the factory to charge additional fees during production. In addition, international shipping costs also significantly increase the order value, especially for small and medium quantity orders.

Figure 3. Additional charges incurred during the JLC circuit ordering process

2. Order through a domestic intermediary unit

Currently, in addition to choosing to order directly from international manufacturers, customers can also choose to use the services of domestic units. Currently, ordering PCB circuits from Chinese factories has become quite popular due to low prices and quality. Compared to ordering directly from international manufacturers, ordering through an intermediary unit has the following advantages:

Optimizing costs

Domestic intermediaries often have cheaper prices than ordering circuits directly from JLC.

Direct support consultation in Vietnamese

Domestic intermediaries often have a Vietnamese support team, helping to explain the process, technical requirements and support troubleshooting more easily. This is especially useful for businesses and individuals who are not familiar with the interface and requirements of foreign manufacturers.

Minimize errors during processing and transportation

With a flexible production process and continuous information exchange, customers can directly confirm the sample circuit as well as monitor production quality. In addition, the quality control and product packaging process helps customers minimize risks compared to ordering from international units.

Support for transportation and customs

When ordering through an intermediary, you do not need to handle the delivery, payment and customs processing. Thanks to that, orders are faster and safer, minimizing transportation costs.

However, it is necessary to choose a reputable unit that can provide full invoices and documents as well as ensure delivery time.

3. Recommendations

3.1. Order circuits through a domestic intermediary

When you want to optimize costs.

When you want to simplify your workflow, reduce the hassles associated with customs and shipping, ordering through an intermediary can help ensure a smoother process.

Manufacturing with special requirements: If your product has specific requirements for specifications, quality, and high technical control, the support of an experienced intermediary partner can help you achieve the expected results

Note that you need to choose a reputable unit to ensure full invoices and documents as well as ensure progress and circuit quality

3.2. Order circuits at Hatakey Electronics

Currently, Hatakey is providing a full range of services from ordering PCB printed circuit boards, supplying components, SMT soldering, to loading code, testing, assembling and packaging to complete finished products. With many years of experience in the electronics field as well as partnerships with many factories and large component suppliers, we are confident that we can fully meet the requirements of customers. Bring customers the best products at the most competitive prices.

In addition, Hatakey currently offers a variety of circuit ordering modes from DHL mode (7-10 days) to regular circuit ordering mode (12-16 days) to meet a variety of customer requirements from fast sample circuit orders to quantity orders that require price priority.

Ordering circuits through Hatakey, you can be completely assured of product quality as well as minimizing risks during transportation as well as invoices, documents, or customs declaration.

4. Conclusion

The final decision in choosing a manufacturer depends on the specific needs of the project, your technical control ability and the priority of price, time, as well as support services. For projects, high-value orders with high technical and precision requirements, you should choose reputable intermediaries such as Hatakey. For sample quantity orders, requiring quick time, you can directly place orders through JLC.

Hopefully this analysis has provided you with a comprehensive and in-depth view of the two options above, helping you make a decision that suits your project requirements.

Currently, Hatakey is providing a full range of services from PCB, components to welding. Please contact us for advice and quotes.

Sales 01: 0965 833 553

Email 01: hatakeyvn@gmail.com

Sales 02: 0927 277 222

Email 02: sales.hatakeyvn@gmail.com

Service feedback: 0971 687 227

Tiếng Việt

Tiếng Việt