Guide to Selection, Application and Testing of Conformal Coatings for PCBs

With the increasing popularity of electronic devices and compact circuits, the demand for conformal coatings after PCBA has skyrocketed, affirming its important role in many applications related to printed circuit boards (PCBs). Choosing the right type of coating and application method for your electronic device is of utmost importance. However, handling the large amount of information available online can sometimes be a daunting task. In this article, Hatakey Electronics will provide all the information needed to determine the ideal type of protective coating for your application requirements. We hope that this article is useful for both beginners who want to learn about the methods and applications of conformal coating, as well as for experienced electronics professionals and manufacturers who want to validate and test their processes.

1. What is conformal coating?

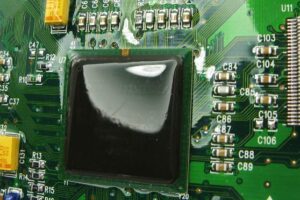

Figure 1. Conformal coating for the board after PCBA processing

Conformal coating is a thin layer of Polymer film used to protect printed circuit boards and other electronic components from adverse environmental conditions. These coatings “shape” according to the shape and structure of the components on the PCB board. They provide good insulation, ensuring that the operation and performance of the board are not affected during operation, while protecting the board and components from environmental factors such as corrosion, humidity, high temperature, mold and airborne pollutants such as dust, etc.

The choice of coating material is often based on the application of the PCB board, the requirement for the level of protection as well as the operating environment of the board. In addition, the ability to perform board rework and the coating method are also important factors to consider when choosing a coating type, but are usually only considered after determining the required protective performance.

Conventional protective conformal coatings are resin-based and can be diluted with solvents or (in rare cases) with water. These conventional coatings are semi-permeable, so they do not completely enclose the coated electronic board. They provide resistance to environmental impacts, increase the durability of the PCB while still allowing for easy repair. However, they are “NOT” completely waterproof.

These conventional coatings are basically classified by resin type, in which the chemical composition of each coating determines its main properties and functions. Choosing the right protective coating for your application is determined by the requirements and operating environment of the electronic device.

Acrylic Resin Coating (AR)

Figure 2. Acrylic Coating for PCBs

Acrylic coatings are a general protection solution. They are characterized by good electrical insulation and corrosion resistance, and a good level of moisture resistance. The distinguishing feature of acrylic coatings compared to other resin coatings is that they can be easily removed with a variety of solvents without the need for mixing. This makes repair and maintenance (even on-site repair) simple and saves both time and money. However, because acrylic coatings do not protect against solvents and solvent vapors, they can lead to suboptimal performance in applications such as fuel pumps, etc. Therefore, acrylic coatings are often considered a basic and popular protection option because they are economical, have good electrical insulation, and provide a good level of protection for common applications.

Silicone Resin Coating (SR)

Silicone coatings provide superior heat resistance. It also has good chemical resistance, moisture resistance, and salt spray corrosion resistance. Due to its rubbery nature, silicone coatings are not very abrasion resistant, but they do withstand the effects of vibration. They are often used in high humidity environments. Special formulations allow coatings to be applied to LEDs without causing color change or loss of intensity, making silicone coatings a popular choice for applications such as outdoor advertising signs. However, removing silicone coatings can be difficult, requiring specialized solvents, long soaking times, and agitation with brushes or immersion in ultrasonic cleaning tanks.

Urethane (Polyurethane) (UR) Coatings

Urethane protective coatings are known for their excellent resistance to moisture and chemicals, as well as their high abrasion resistance. This combination with solvent resistance creates a coating that is very difficult to remove. Similar to silicone, complete removal of urethane coatings often requires specialized solvents, long soak times, and agitation with a brush or ultrasonic cleaner. Urethane coatings are often specified for aerospace applications where there is a possibility of exposure to fuel vapors.

Epoxy Resin (ER) Coatings

Epoxy resins (ER) are typically supplied as two-component compounds and form a very hard coating. Epoxy coatings provide excellent moisture resistance and are typically impermeable, unlike traditional coatings. They also have high abrasion and chemical resistance. Epoxy coatings are typically difficult to remove after curing and are not as flexible as other materials. These coatings are often used in potting compounds, which completely encapsulate electronic components in a uniform layer of material.

Parylene Coatings

Parylene protective coatings are a unique type of coating applied using a vapor phase deposition method. It provides excellent electrical insulation and excellent resistance to moisture, solvents and temperature extremes. Using a vapor deposition method, Parylene coatings provide a thin coating that still provides effective board protection. However, removing the coating for repair is difficult, requiring abrasive techniques, and without vapor deposition equipment, recoating Parylene is not possible.

Thin “Nano” Film Coatings

These are coatings that are dissolved in a fluorocarbon-based solvent and applied by spraying or dipping to create a thin layer, although not at the nanometer scale as the name suggests. They have minimal water resistance to prevent damage when the device is exposed to water for very short periods of time, but do not provide the same level of surface protection as other methods.

2. Conformal Coating for PCBs

Once the appropriate coating has been selected, the next question is how to apply it to the PCB surface. This decision will be based on the following factors:

- Production capacity requirements: Preparation work, coating process speed, and coating cure rate…

- Board design requirements: Does the design have many connections, solvent-sensitive components…?

- Equipment requirements: Based on an assessment of production capacity as well as order volume and frequency, as some coating methods will require specific coating equipment such as selective spot coating machines, UV curing ovens, etc.

- Pre-coating treatment: Some processes require masking or tape before applying the coating to prevent coating from being applied to unwanted surfaces.

- Quality Requirements – Critical electronics, requiring high repeatability and reliability, often require automated application methods as well as rigorous quality control procedures…

Traditional methods of applying protective coatings include:

- Manual spraying: Protective coatings can be applied using an aerosol sprayer or hand-held spray gun. This method is often used for low-volume production where no investment equipment is available. This method can be time-consuming due to the need to mask off areas that do not need to be coated, and the results are highly dependent on the skill of the operator, causing variation from board to board.

Figure 3. Using a sprayer to apply a protective coating to the circuit board surface.

- Automatic spraying: Using a programmed spray system, the board is moved on a conveyor belt under the spray head. There is also an automated process that uses pre-programmed robotic sprayers to apply the protective coating only to specific areas of the board. This process is suitable for high volume production and can eliminate the need for masking. Some systems also incorporate UV lamps to cure the coating immediately after spraying onto the board surface.

Figure 4. Selective conformal coating system.

- Dipping: The printed circuit board is dipped into the protective coating solution and then withdrawn. The dipping speed, withdrawal speed, immersion time and viscosity of the solution determine the film formation. This is a common technique in high volume production, but often requires masking of large areas before proceeding. This method is only feasible when coating on both sides of the board is acceptable.

Figure 5. Conformal coating by dipping.

- Brushing: This is a simple technique, mainly used for repair and remanufacturing applications. The protective layer is applied by brush to specific areas of the board. This method is low cost but requires a lot of manual labor and the results are highly dependent on the skill of the operator, so there is a high variability. This method is best suited for small production batches.

3. How to measure conformal coating thickness

Adhesive coatings on boards are usually very thin in thickness to provide maximum protection while using the least amount of material possible. This thinness helps to minimize heat retention, unnecessary bulk, and other issues. The typical thickness of most coatings is between 1 and 5 mils (~25 and 127 microns), with some special materials or circuits being even thinner. Any coating thicker than this is generally considered an encapsulate or potting compound, providing greater bulk and thickness to protect the board.

There are three main methods for measuring the thickness of a protective coating:

- Wet film thickness gauge: The film thickness can be measured directly using a suitable gauge, which contains calibrated grooves and notches. The gauge is placed directly on the wet coating on the board surface to measure the thickness, then the measurement is multiplied by the percentage of solids in the coating to calculate the approximate dry film thickness.

Figure 6. Wet Coating Thickness Gauge

- Micrometer: The board is checked for thickness with a caliper at multiple locations before and after coating. The cured coating thickness is obtained by subtracting the uncoated board measurement, dividing by two to obtain the coating thickness on one side. The standard deviation of the measurements is calculated to determine the uniformity of the coating. This method is best suited to hard coatings that do not deform under pressure.

Figure 7. Using a caliper to measure the thickness of the board before and after the conformal coating process.

- Eddy current probes: This method uses a test probe to create an oscillating electromagnetic field, thereby directly measuring the thickness of the coating. The measurement results are non-destructive and highly accurate, but depend on the presence of a metal substrate or metal under the coating, as well as the ability of the test sample to directly contact. If the measurement area has no metal under it, the measurement cannot be performed; or if the probe is not in flat contact with the surface, the result will be inaccurate.

Figure 8. Measuring conformal coating thickness with an eddy current gauge

- Ultrasonic thickness gauge: This device measures coating thickness using ultrasonic waves. Its advantage over eddy current sensors is that it does not require a metal substrate. Thickness is determined based on the time it takes for the sound wave to travel from the transducer through the coating, to the board surface, and back. A conductive medium such as propylene glycol or water must be used to ensure good contact with the surface. This method is considered non-destructive unless there is concern about the effect of the conductive medium on the coating.

4. Curing Methods

Although the curing mechanism is not the primary criterion when selecting a conformal coating, it directly affects the coating method and production capacity. Some mechanisms are very simple, while others are complex and can cause errors if not strictly controlled during the curing process.

Figure 9. Cured protective coating and UV irradiation.

- Evaporative Curing Mechanism: In this mechanism, the liquid portion of the conformal coating evaporates, leaving only the resin portion of the coating. Although the theory is simple, boards often need to be dipped at least twice to create a sufficiently thick coating at the edges of the component. Whether the liquid portion of the coating is solvent-based or water-based, humidity will affect the curing process. Solvent-based coatings are easy to handle, providing a uniform coating due to their good wetting properties and fast cure times. However, solvents are often flammable, so adequate ventilation and a suitable fume extraction system are required. Using water-based coatings eliminates the fire problem, although the coating may take longer to cure and is sensitive to ambient humidity.

- Moisture Curing: Mainly used with silicone and urethane curing adhesives. These materials react with moisture in the air to form a polymer layer. Usually, this mechanism is combined with evaporation curing, when the solvent evaporates, the moisture interacts with the resin component to trigger the final curing process.

- Heat Curing: Heat curing can be applied to single or multi-component curing adhesives, and even as a secondary curing mechanism for UV, moisture or evaporation curing systems. The addition of heat aids the polymerization process or accelerates the curing process. This method can be useful when a single curing mechanism is not sufficient to achieve the required requirements. However, attention must be paid to the thermal sensitivity of the board and components when using high heat.

- UV Curing: UV curing allows for very high productivity. This method is used with 100% solids adhesives, containing no solvents or water. The UV curing process takes place directly on the production line, therefore requiring a secondary curing mechanism for areas hidden by components that cannot be reached by UV light. UV cured coatings are difficult to repair, requiring UV curing equipment and UV protection for the operator.

5. How to Remove Conformal Coating

Sometimes, it is necessary to remove a protective coating from a circuit board to replace a damaged component or perform other repair procedures. The method and materials used to remove the coating depend on the type of coating and the size of the area to be removed, which also affects the time it takes to remove it.

Some basic methods listed by the IPC include:

- Solvent Removal: Most protective coatings can be removed with solvents; however, it is important to determine whether the solvent will damage the components or connectors on the board. Acrylic coatings are very sensitive to solvents and are easy to remove, while epoxy, urethane, and silicone coatings are less sensitive. Parylene coatings cannot be removed with solvents.

- Peeling: Some protective coatings, primarily some silicones and flexible coatings, can be peeled off the board.

- Thermal/Burn‐through: A common technique is to use a soldering iron to burn through the coating during board repair. This method is effective for most types of protective coatings.

- Microblasting: This process uses a mixture of soft abrasives and concentrated compressed air to abrade and remove the protective coating, often applied to small areas, especially when removing Parylene and epoxy coatings.

- Grinding/Scraping: The coating is removed by grinding the surface of the board. This method is effective for hard coatings such as Parylene, epoxy, and polyurethane, but should only be used as a last resort because it can cause serious damage to the board.

If the job is simply to replace a component or repair a small area, the coating is often simply heated through with a soldering iron tip. In cases where this is aesthetically unacceptable, or could be harmful, or where components are densely packed, coating removal solvents may be used.

6. Conformal Coating Standard Certifications

Certifications are an important factor in distinguishing between adhesives and coatings specifically engineered to protect PCBs. While there are dozens of consumer and industry standards, the two most common certifications are IPC-CC-830B and UL746E. So when selecting a coating, look for third-party testing documentation rather than relying solely on a “meets requirements” claim. Both standards use the UL94 standard to evaluate flame retardancy, with a V-0 rating indicating the lowest level of flame retardancy.

- IPC-CC-830B / MIL-I-46058C: This standard is derived from the military standard MIL-I-46058C (obsolete since 1998). The consumer version of IPC-CC-830B is almost identical, so it is generally understood that if a board passes the IPC standard, it will also pass the MIL standard, and vice versa. IPC-CC-830B includes a series of tests – some are pass/fail, others provide reference data for criteria such as: Appearance, Insulation resistance, UV fluorescence, Fungus resistance, Flexibility, Flame resistance, Moisture and insulation resistance, Thermal shock, Hydrolytic stability

UL746E Underwriters Laboratories (UL): is considered a globally respected safety certification organization, and UL certification is often required for consumer products. The UL746E standard tests the electrical safety and flame resistance of electronic devices coated with conformal coatings. For electrical safety, the test is similar to IPC-CC-830B but with a cyclic current load to continuously measure the degradation of electrical insulation. The flame resistance test uses the UL94 standard, in which the coating is exposed to a flame and its ability to sustain the flame is observed. - Once a coating passes the UL746E standard, it can be registered with UL and assigned a registration number. Products certified to this standard may display the UL symbol (which looks like “UR” spelled backwards). To maintain registration, the coating must be retested annually.

Note that some coatings are only tested to a portion of the overall standard. For example, if flame resistance is a primary concern, a coating may only be tested to the UL94 standard. Some specialty coatings may not pass all of the IPC-CC-830B or UL746E tests due to the nature of the product and its specific application – this does not necessarily reflect the overall quality of the product. For example, some LED coatings remove the UV rating to avoid color change, but this would cause the coating to fail the IPC-CC-830B standard for UV transmittance.

7. Safety Regulations for Conformal Coating

Safety and environmental issues should always be considered in the selection of chemicals and the design of the manufacturing process. However, different regulatory agencies can impose complex requirements that require interpretation and compliance with product specifications.

- OSHA (Occupational Safety and Health Administration): In the United States, OSHA has ultimate authority on worker safety. Many coatings are highly flammable and can emit highly toxic vapors. Therefore, attention must be paid to ventilation (to ensure explosion protection when handling flammable vapors) as well as appropriate personal protective equipment (PPE) to reduce operator exposure to below safe levels. Ensuring that flammable solvents are not used may require seeking water-based coatings.

- EPA (United States Environmental Protection Agency): In the United States, EPA requirements must be followed at both the national and regional levels. Under the Montreal Protocol, EPA has imposed restrictions on ozone-depleting chemicals. However, since most of these restricted chemicals have been phased out of the formulation of conformal coatings over the years, ozone is no longer a major concern today.

- CARB (California Air Resources Board) and other regional regulations: Local agencies are playing an increasingly important role in environmental restrictions. CARB was one of the first agencies to set restrictions on VOCs (volatile organic compounds – chemicals that contribute to smog formation) by product category. Other regional agencies have followed suit. Global warming potential (GWP) has been a topic of recent interest.

Conclusion

Through this article, Hatakey Electronics has shared basic knowledge about the coating process as well as coating methods for electronic circuit boards after completion as well as how to choose the appropriate coating process for your electronic products.

If you have any questions or need advice on the coating process for your circuit board products, please contact us here for support!

Sales 01: 0965 833 553

Email 01: hatakeyvn@gmail.com

Sales 02: 0927 277 222

Email 02: sales.hatakeyvn@gmail.com

Service feedback: 0971 687 227

Thank you very much!

Tiếng Việt

Tiếng Việt