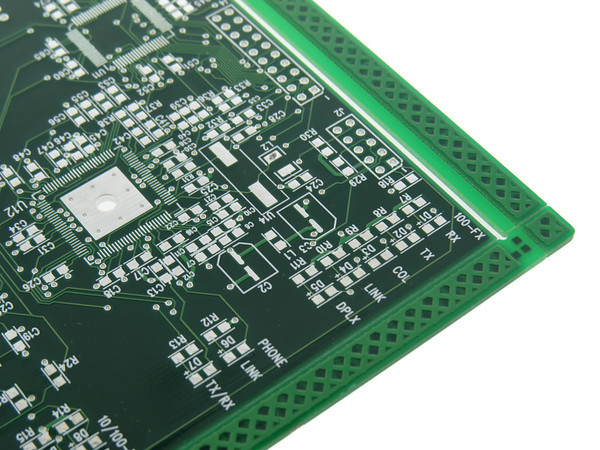

With the development of industry, users now have more PCB colors to choose from. These include green, blue, white, red, black, purple and yellow (Figure 1). However, green has always been the most popular color. So what makes green the main color choice for PCB boards?

Figure 1: Colors used in PCB circuit boards.

Advantages of using green for PCB circuits

1. Cost savings.

Green PCBs are one of the most widely used and popular types. Therefore, the cost of large-scale production is relatively low. This makes them a more economical solution. Therefore, many manufacturers choose green as the main color for their products.

2. Easy to saturate with developer.

During the PCB manufacturing process, chemicals are needed to remove unwanted components. Green is easier to saturate with developer. Therefore, it is easy to remove unwanted components on the circuit board.

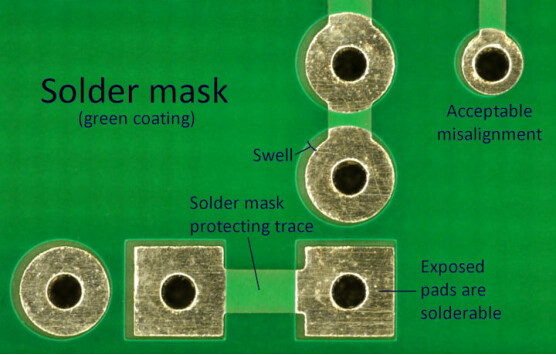

3. Has a good visual effect.

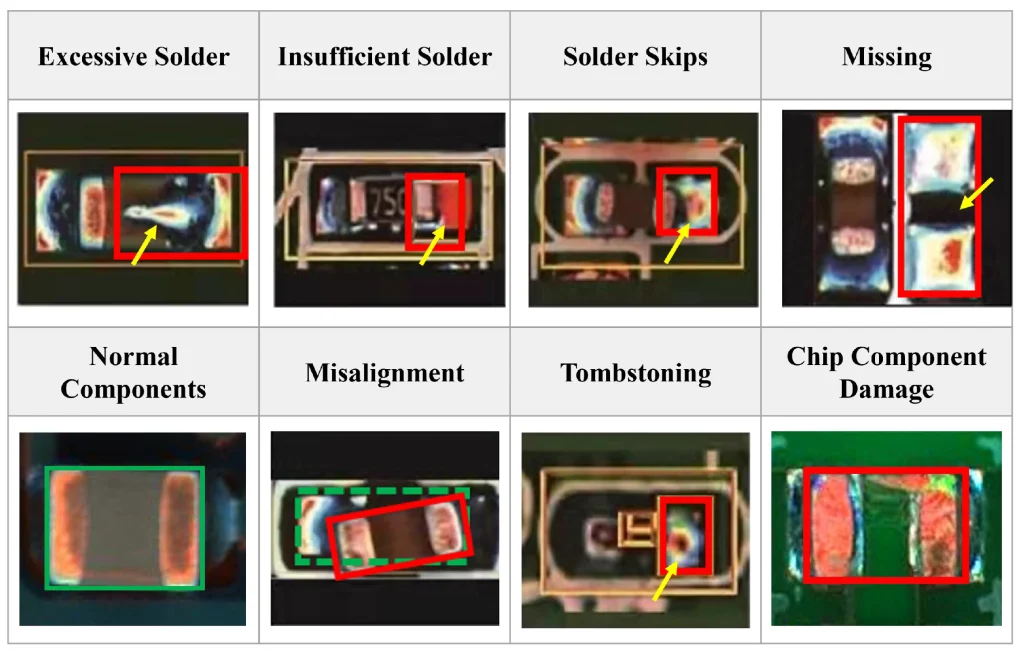

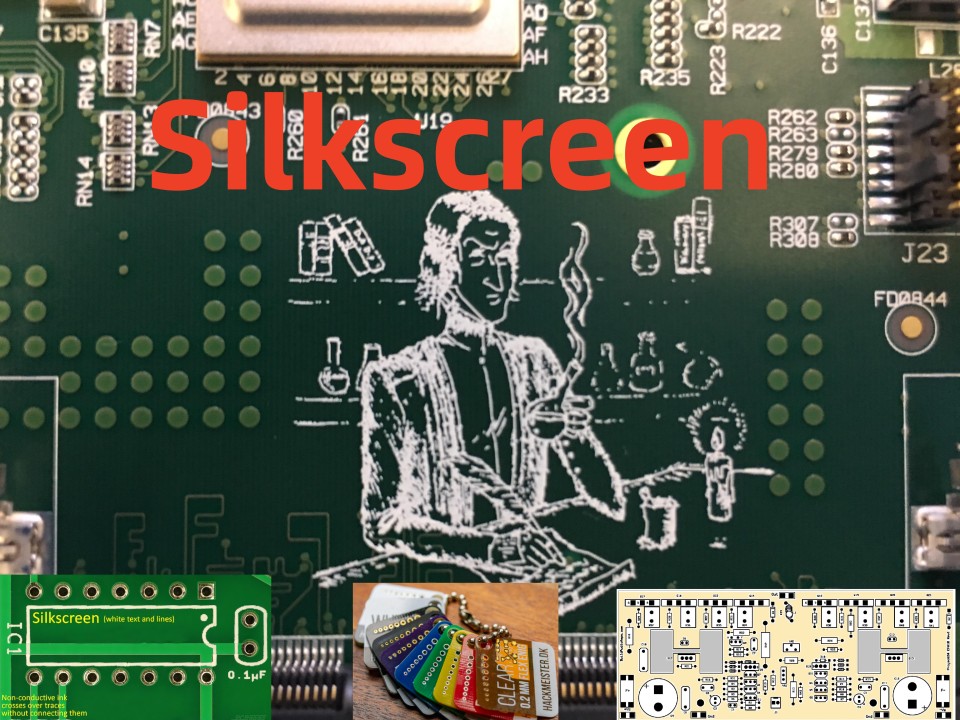

The green color of the PCB increases the contrast of the metal solder pad and the high-brightness display layer. This makes it easier to identify and maintain the board. Due to current manufacturing processes, many quality control steps still rely on human observation. Looking directly at the light for a long time will cause eye fatigue. In addition, green is the color that causes the least eye fatigue when compared to other colors. In the PCB manufacturing process, the entire product usually goes through the processes of circuit board making and SMT. During the SMT soldering process, the PCB goes through the steps of solder paste application, component placement, and AOI verification. The green background color improves the recognition accuracy of these processes.

4. Better security.

Green PCBs make it more difficult for others to guess and copy the design of the circuit board than uncoated circuit boards. Some manufacturers choose black PCBs for added security because black makes it more difficult to see the wiring system inside the circuit, which makes reverse engineering more difficult.

5. Relatively safe and environmentally friendly.

Compared with other colors, green PCBs are safer and more environmentally friendly. For example, blue and black contain cobalt and carbon, which have certain conductive properties and are likely to cause short circuits when powered. On the contrary, green has a lower risk of short circuits. In addition, green PCBs usually do not emit toxic gases when used in high temperature environments.

Conclusion:

So we have completed learning about the colors used in PCB circuits and why green has become the main color in PCB production. If you have any difficulties in the learning process, please contact the technical team of our company HATAKEY Electronics to get detailed and specific answers to all your questions.

Currently, Hatakey Electronics.com.vn specializes in providing services related to PCB circuit boards with various sizes and colors, meeting all customer needs.

Tiếng Việt

Tiếng Việt